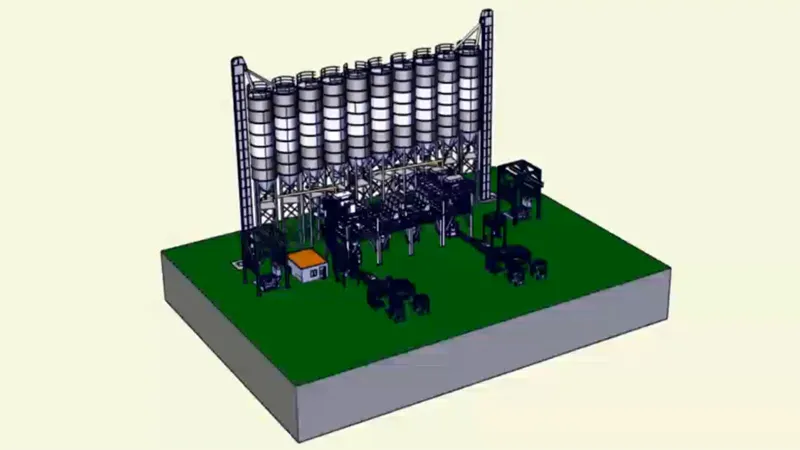

Tile Adhesive Production Plant

Complete dry mixing plant for the production of tile adhesive

Tile Adhesive Production Plant

Complete dry mixing plant for the production of tile adhesive

- Capacity of production line 10-30 tons/hour

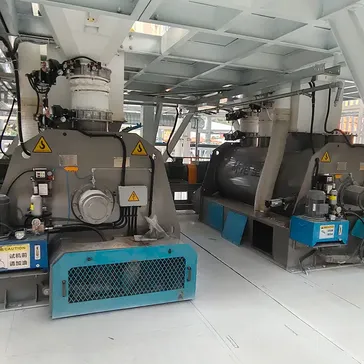

- Capacity of mortar mixer 15-88 tons/hour

Our tile adhesive production plants are designed for manufacturing a variety of polymer-modified cement-based adhesives, with a flexible annual capacity ranging from 100,000 to 300,000 tons. By customizing raw material formulations, the plant efficiently produces adhesives tailored to different market needs, such as standard adhesives (Type 1), high-strength adhesives (Type 2), and specialized adhesives for large tiles or marble (Type 3).

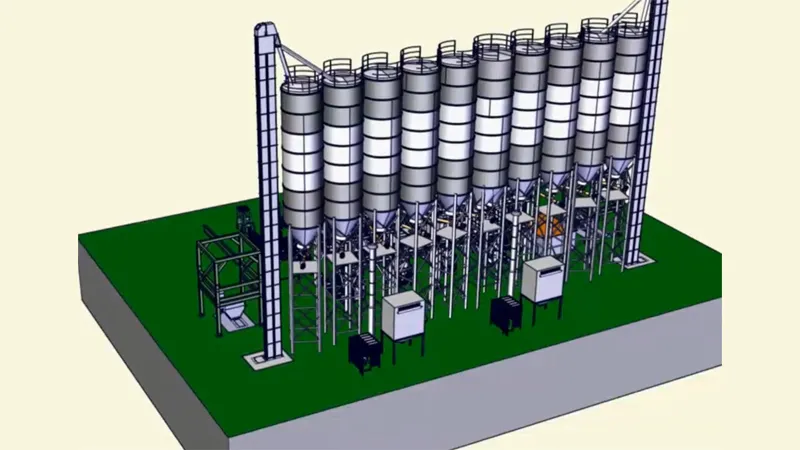

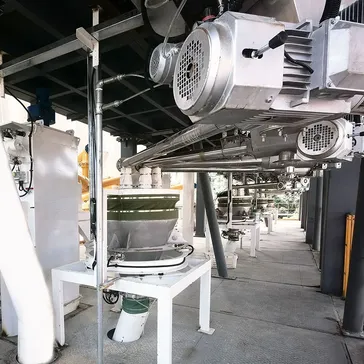

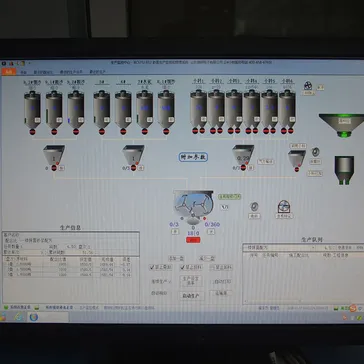

Depending on the chosen configuration, the hourly production capacity ranges between 10 to 30 tons. The tower-style structure places the powder silos at the top of the main processing building, facilitating efficient material flow. Additives are precisely metered and pumped via an independent platform dosing system. Raw materials then pass sequentially through weighing systems, high-performance mixers, finished product silos, and automated bulk loading or packaging units.

To ensure consistent product quality, formulations are precisely controlled by computerized weighing and batching systems. Materials are evenly mixed according to specific recipes, and tile adhesive products are available immediately after mixing. The entire production process is fully automated and intelligently controlled, delivering consistent performance and efficiency.

Each tile adhesive processing line typically utilizes 3-6 raw material silos depending on the specific formulation. For quality assurance, it's recommended to limit the number of product variations per line to a maximum of three and ensure production lines are dedicated to compatible formulations to prevent cross-contamination.