Automatic Bagging Equipment

Individual machines for dry mix mortar production

Our automatic bagging equipment features a high level of automation, integrating electronic weighing, automatic bag removal, and dust control. Designed for efficiency, it ensures precise packaging with an accuracy within 200g and operates at a speed of 180 to 220 bags per hour.

-

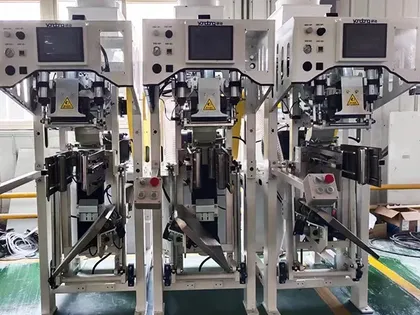

- Forced Air Valve Bag Filler The forced air valve bag filler handles accurate, efficient filling of large valve bags (10-50 kg) with abrasive powdered or granular materials. Using a gentle, continuous low-pressure method, it prevents material damage and separation during filling. Integrated electronic weighing, automatic bag removal, and dust control capabilities ensure precise results within ±200 grams at speeds between 180 and 220 bags per hour. View Details

-

- Impeller Valve Bag Filler Our impeller valve bag fillers can efficiently handle the packaging of abrasive powder and granular materials into valve bags ranging from 10 to 50 kg. Equipped with ultrasonic sealing technology, these bag fillers ensure bags are securely sealed with high accuracy and speed. It seamlessly combines electronic weighing, automatic bag releasing, and effective dust removal into one fully automated solution, simplifying the packing process and improving productivity. View Details

-

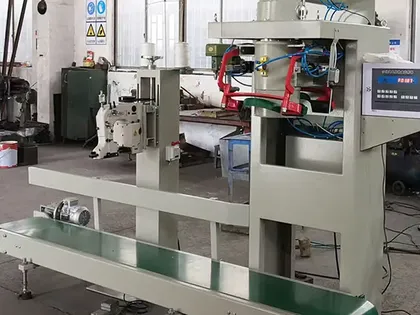

- Open-Mouth Bagger Efficient packaging of granular and coarse powder materials is essential across various industries. To address this need, Huangang offers an automatic open-mouth bag filling system built with premium 304 or 316L stainless steel parts that directly contact materials. Using a gross-weight scale and a double screw feeding mechanism, bags ranging from 10 to 50 kg are accurately filled and securely sewn shut, preventing product spillage and contamination. View Details

-

- Bulk Bag Filler Efficient bulk handling of powders and granular materials is important for industries dealing with large-volume packaging operations. Our bulk bag filler offers a comprehensive solution tailored to simplify and enhance the filling and packaging process of bulk bags (FIBC bags). These bag fillers combine precise electronic weighing, automatic bag release, and integrated dust control, resulting in fast, accurate, and environmentally friendly packaging operations. View Details